Paper and the Circular Economy: Why Your Parking Tickets & Receipts Rolls are Truly Sustainable

The paper industry uses more renewable energy than any other industrial sector.

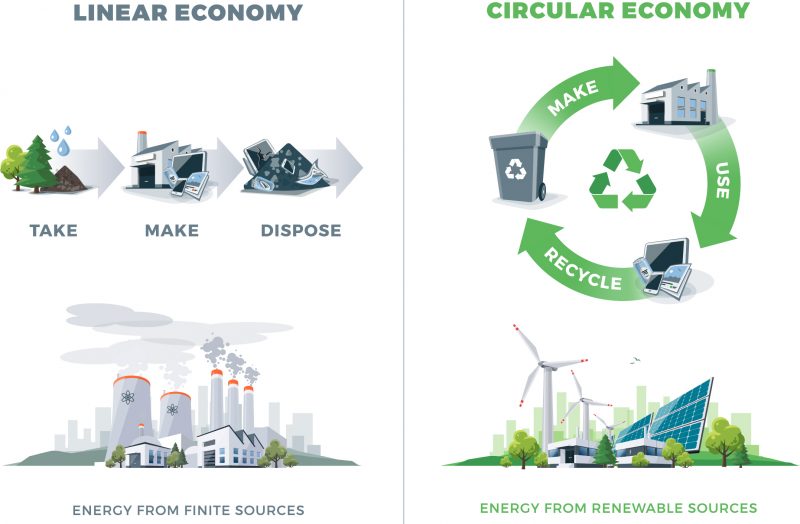

Recent stories about the impact of materials in our waste streams – like plastic in our oceans, or the increasing amounts of electronic waste – have changed how companies think about the materials used in their manufacturing process. There is a movement to get away from the ‘one-and-done’ model of the linear economy, toward a more “circular economy,” where the reuse, refurbishment, recycling, and end-of-life disposal of a product factors into the manufacturing design. In a circular economy, manufacturing is done in a way that builds the overall health of the process – financially, environmentally and socially.

Large corporations like Starbucks and McDonald’s are looking for ways to minimize plastic packaging with their straws and cups. Packaging suppliers are investing in research to develop coatings that make paper as convenient and practical as plastic, but also biodegradable and recyclable. From gift cards to Apple iPhone packaging, companies are evaluating and often redesigning their process to incorporate more sustainable materials.

Paper is a natural fit for the circular economy model. Paper-based materials are becoming the go-to replacement as companies look for more sustainable ways to produce their products. Wood, paper, and paper-based products, in many circumstances, tie into the circular economy model because of the following facts:

- Paper is one of the few truly sustainable products. Each year, forests in North America grow significantly more wood than is harvested. North American forests are a renewable resource that is continuously replenished using sustainable forest management.

- Paper is highly recyclable. Paper is recycled more than any other commodity in the solid waste stream and is often the dominant raw material used in paper production. A combination of fresh wood supply and recycled paper allows printing and writing paper to be down-cycled to other products like corrugated boxes, tissue, and other packaging.

- Much of the energy used for papermaking is renewable. Roughly two-thirds of the energy used by North American pulp and paper mills is self-generated using renewable biomass in combination with heat and power (CHP) systems. The paper industry uses more renewable energy than any other industrial sector.

There is still a significant amount of work needed to measure the overall life cycle benefits of making these manufacturing shifts, but companies are reviewing the environmental impact of their processes and products in a more complete way. The sustainability of wood and paper continues to play an important role in the move from a linear to a circular economy.

Image credit: iStock.com/petogarva